I have a five old daughter named Zoey. She likes to work on cars and she loves my Honda. During my last post I reported my dipstick hanging out as if crank case pressure pushed it out. Come to find out while I was investigating the oil under my car Zoey decided to check my oil for oil me. When she put back the dipstick, she didn't push it down far enough. She is so cute for trying to help! I was reading her a story a few nights ago and she told me what she had done.

Relief number one: crank case pressure did not push out my dip stick.

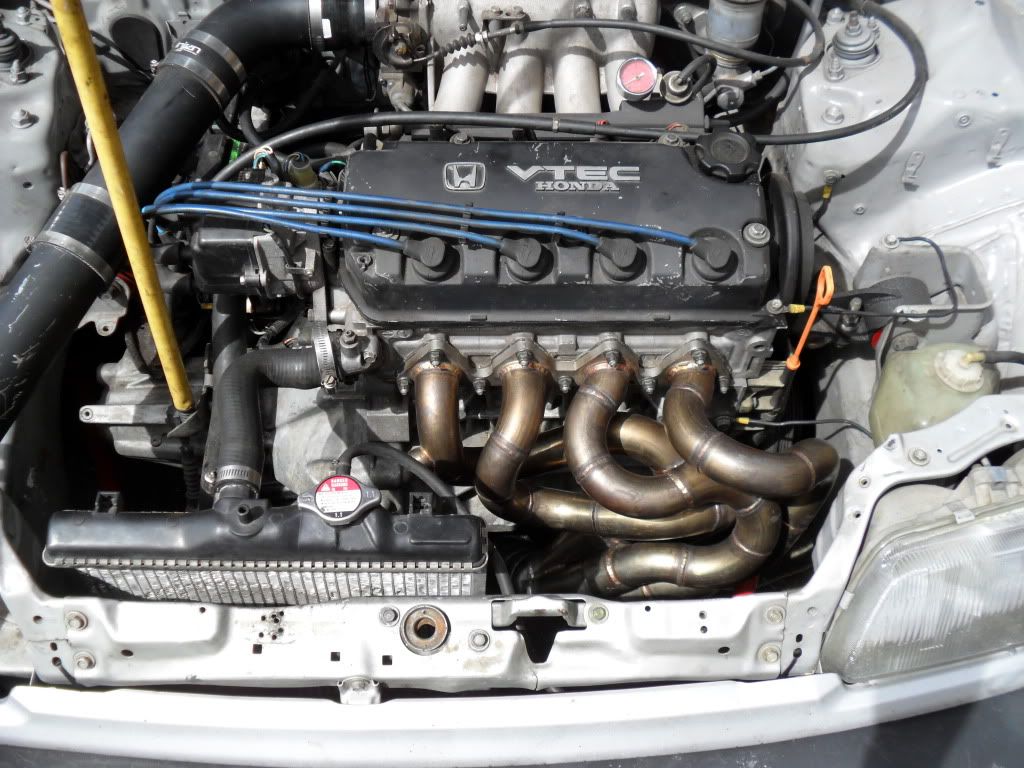

Days ago I had poured in Brad Penn oil. About 15 minutes after this I noticed oil started to leak. It almost looked as if the header itself was leaking! Clearly something cracked and I prayed that the oil was not coming out of my header. I removed my header and bam- the oil pan was cracked...

I had the brace on the megaphone too loose. Somehow the seam on the megaphone rubbed that hole in from the lack of tension on the megaphone.

Relief number two: oil didn't leak out because of crank case pressure. Yay!

When it rains, it pours. My Jeep's thermostat housing started to leak coolant. Two bolts hold on the thermostat cover. The first bolt came out okay, but the second bolt snapped. I tried and tried, but I could not get the bolt to come out. Both of my vehicles were down.

My wife and I found a local welder, Wagner Prop Shop that was only a few miles away. We walked over to their shop with my oil pan. The staff there was awesome! Not only did they weld my oil pan right away they only charged my $15 bucks. Here's the results...

I installed the oil pan, new plugs gapped at .035", and my header. This time I tightened the brace a little more so it can't move.

My lawn mower battery just didn't have the CCA that it used to. I had to get another battery. I wanted to do a compression test but that damn battery just couldn't do it. I didn't want to walk 10 miles to the next Walmart to get another battery. So I jump started my Civic and drove down to Walmart.

I am glad to report that my engine ran like a dream to Walmart and back. I recently put in a few gallons of VP 110 race fuel*. Combined with new plugs my motor really felt nice. I'm sure thirty two degree ambient temps helped out as well.

There at Walmart, I picked up another lawn mower battery that has 275 CCA compared to my old batteries 230 CCA. Once installed the new battery had no problem getting my engine started. I installed the battery at Walmart. I'm glad to report that I have no oil leaks and my dip stick did not pop out. Everything motor wise is checking out nicely so far.

I plan to do a compression test during my lunch break at work tomorrow. More updates soon. Thanks for reading!

*Some of you may remember that I spoke of switching to E85 fuel. Last June E85 had a significant blend change. In my area E85 is more like E70 and carries only a 95ish octane rating. VP 110 has an octane rating of 107 and was formulated for engines that have 12 - 14.0 compression ratios. I decided to stick with VP fuel at this time.