To reach my goal of running 13's all motor I knew that I would need a lot of compression, the biggest engine I could possibly afford and a proper close ratio gear set. Being the broke family man that I am, I stuck with a d16 engine. I started with a d16y7 block and crank. I used this block in the past but had boosted it. In a past life this y7 was fed 13 psi from a 44 trim turbo for two years. I sold the turbo parts I had and tore down the engine for all motor duty.

Compression plays a major factor in making power especially at my elevation. In my area of Colorado Springs, Colorado the elevation is over 6000 feet. My local track is over 5000 feet about sea level and has a dense altitude of over 8000 feet above sea level. The best pistons I could afford is a set of Nippon Racing p29 pistons.

Before you go thinking, "oh God, he has those pistons," hear me out. I'm not going to go into flame propagation or theories on combustion. I know of three cars in Puerto Rico running 12's with p29 pistons. They can get the job done.

I couldn't find a set of p29s in 76mm so I had to settle for 75.5mm. I had my favorite local shop, Lee's Machine bore the block and hot tank it for me. It came out great.

I chose the NPR 75.5mm pistons because of the 30mm compression height. This places the pistons flush with the deck. It looks so nice...

Lee's also set the new pistons on for me. I left the pistons alone and did not modify them. I plan to build a few of these engines and want to take each engine to the next extreme. This engine is pretty basic and will stay that way. Each engine will be an improvement and I have to experiment to see what breaks first.

I used King bearing and ACL thrust washers. Don't ask me, that was the combo that was sent. The crank, the rods and rod bolts are stock and unmodified too. I bought a new oem oil pump from Honda and left it stock too.

After I built this block I had it sitting around in a bag for a couple of months before I needed to use it. I had a ported y7 head with a Delta 272 cam that I was going to run on this bottom end but it dropped a valve with a different bottom end before I could try it on this one. I had a stock y5 vtec-e head laying around and decided to give it a shot. I used an oem y8 head gasket from Honda with stock y5 head bolts. An AEM y8 cam gear, Bisimoto prototype header, 2.5" short exhaust with resonator, stock air box with custom internal air foil, 3" aluminum intake piping, 60mm throttle body, gasket matched Blox intake and DSM 450cc injectors finished out the modifications.

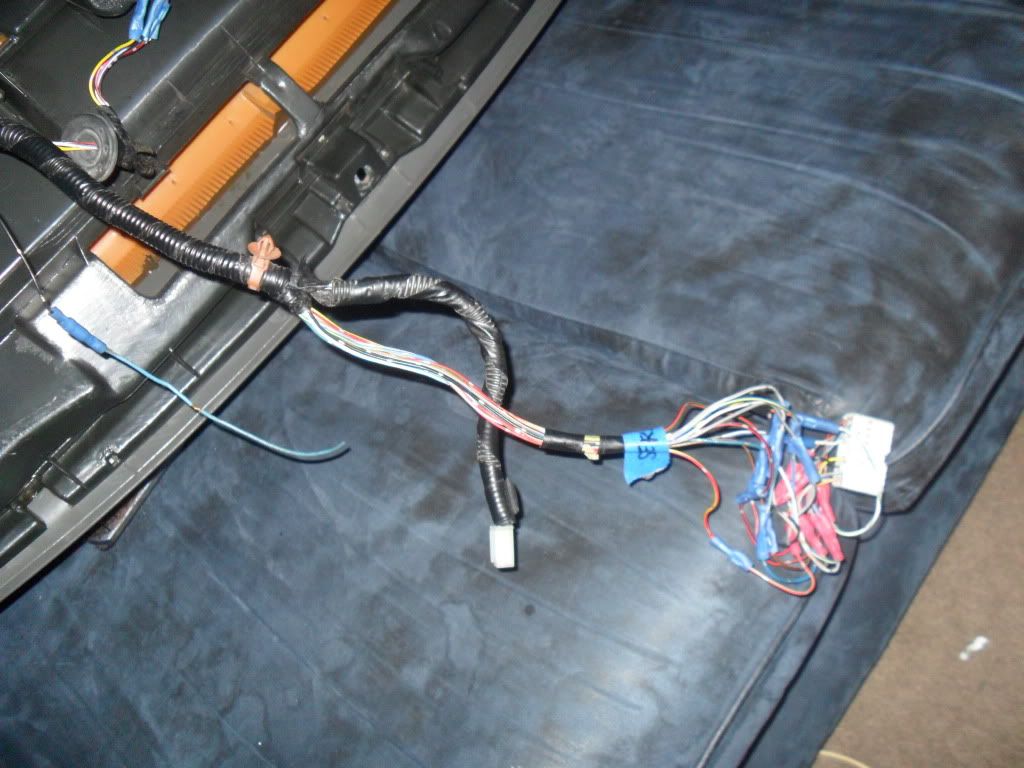

This set up is obdo. I am a tester for the latest ng series of roms that work with TurboEdit and BRE. I have a stock Si distributor, self chipped ps9 ecu, Moates Ostrich 2, Hulog and a Innovate lc1. Using Ecucontrol I was able to tune the engine in rather well.

The engine did have it's quirks. The y5 cam wanted vtec-e to activate as soon as possible. Like at 2000 rpm. Other than that it ran good and seemed to like 25* degrees of total timing and 13:1 afr.

I took this set up to the track once. I had three runs and only one of them went well. The runs were on street tires on the side of the track which lead to horrible 60' foots. Here's a video of the two full runs...

I ran a best of 15.7 @ 88 mph with a 2.58 second 60' foot. Horrible! I know I could do a lot better with a set of slicks and some changes. Before I knew it summer was over and the season ended. That was in 2010.

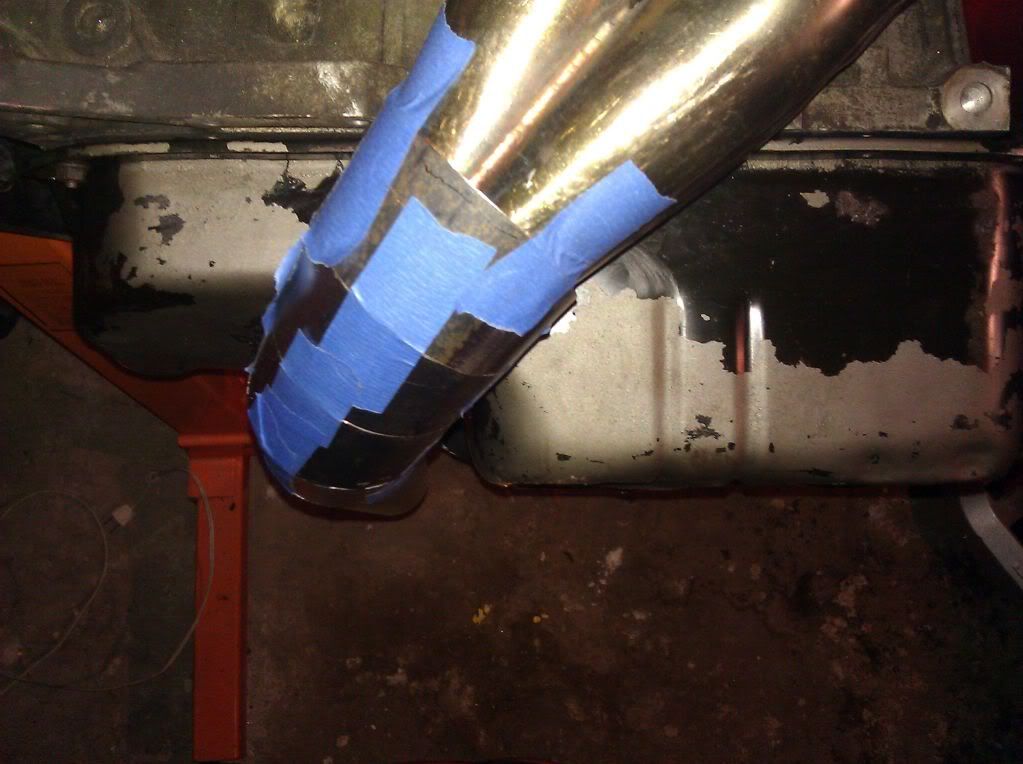

2011 was a slow year in regards to progress. I had the battle with my Bisimoto header that you can read about in another post. That really held up progress and I wasn't able to dyno the set up or buy other parts. While the Bisimoto header was off I was reduced to using a ceramic coated Pacesetter header. I certainly did not want to go to the track and run with that crappy header.

That didn't stop me from making some changes. The first major change was getting rid of the vtec-e parts. I swapped in a y8 cam and y8 rockers. Right away that made a positive improvement in not only the mid range but in the top end as well. I was able to bump up timing to 28* with the y8 cam.

I replaced the stock fuel pump with a Walbro 255 fuel pump. I also ditched the stock air box and went with something that was yielding results for others- a long tube air intake. Not only that, I bought a BPi flow stack to go along with it. I ran the intake down and out of the engine bay. The velocity stack is sticking out of the front bumper. I think it that the long tube intake and velocity stack made more a difference than when I went from the Bisi header to the Pacesetter header.

2012 is already turning out to be a great year. I plan on making more changes, tuning on the dyno, testing parts and hitting the track as soon as it opens! Stay tuned!