I'm going to start this blog by posting about my Bisimoto header adventure. My Bisimoto adventure began when he released his new at that time v2 headers. The hype was big about this header and everyone had high expectations. Bisi lived up to the hype by posting a dpfi d15 that gained almost 16 whp by swapping to his v2 header and an oil change. I had to have one of these headers right away.

At the time Bisi had the custom v2 units at $629 shipped and the prototypes for only $449 shipped. The only draw back between the two is his claim of "less than asethetic appealing welds". The prototype seemed appealing to me as a consumer. The word prototype to me means something that has been tested against another. In this case the prototype must have beaten out another design in order to be good enough for resale. I ordered the header on February 19th and received a tracking number on March 3rd, 2010. The delay in it being shipped to me was due to what Janet at Bisimoto said pressure testing. I received an email stating the my header needed to be pressure tested to ensure that it doesn't leak. I thought cool; they are taking care of me and making sure that the welds can hold pressure.

When I received the header it looked awesome. To my surprise, it hadn't been run before. Hmmmm. I thought that maybe they sent me the wrong header. Then again there was a sticker on the down pipe that had my last name printed on it. Must be for me. Either way I thought I lucked out and got the real deal for some reason. Either way I was stoked and ready to run this beast. It looked sexy on a table.

I installed the header right away. At the time I wasn't driving my '88 Civic much as I had a '90 sedan to daily drive in. I was running it open header. I noticed that with my second o2 bung so close to the end of the exhaust tube I was getting erronious AFR readings. My LC1 would read 19:1 at an idle because so little exhaust was passing by it. I added a flexible pipe and 26" long resonator. That helped and I was able to tune my engine. Weeks pass and I ended up wrecking my sedan. It was totalled out. I had to start driving my '88 while I waited for insurance money to pay for the damage. During this waiting period I put about 2000 miles on my header and started to noticed wildly lean AFRs. I inspected the engine bay and found this:

There were a lot more cracks than that. I don't want to post them all. In fact almost every welded seam cracked. I had a flex pipe and not even an entire exhaust system connected to it. I was not a happy camper.

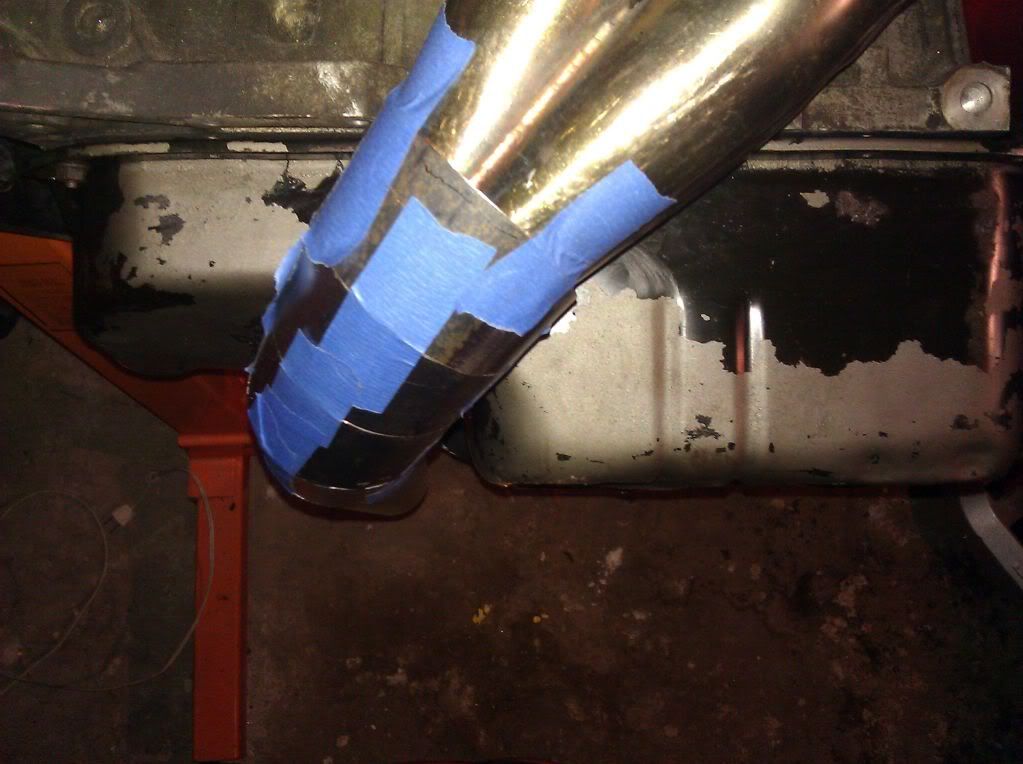

I contacted Bisimoto. They told me to send them the header back and they would determine the damage. Something felt off about the situation and I decided to have it fixed locally. Luckily I found an awesome welder by the name of Al at Precision Welding. He did a great job of fixing it. Check it out:

Can you tell which seams Al welded and which seams are left from Bisi's guy?

For awhile this set up worked. I drove it for about another 6 months before disaster struck again. This time it was right after the collector and the entire downpipe had broken off. I was disappointed but I wasn't ready to quit. I decided to either have Al weld the pipe together and try again or I was going to find someone else to not only fix but make it better too. That's where Matt aka The Acid Beaver came into play. He agreed to not only fix my header but to improve it as well.

We all know that Bisi is an Engineer. There are a lot of Engineers in the world today and not every Engineer is perfect. Due to my engine being only 1611cc, the 2.5" collector and down pipe was a little large. It was obvious as there wasn't enough velocity to give my wideband's o2 sensor any exhaust gases to read. The Beave and I decided to choke the collector down and to add a megaphone reverse cone into the mix. Here's a few pics of Matt getting started...

It's looking sharp so far!

No comments:

Post a Comment